ULTRA-TUFF™

The NEW Standard for Plastic Modular Belting.

Available ONLY from Safari Belting Systems, Inc.

Safari Belting Food Safety Innovations

Safari Belting Systems, Inc. introduces ULTRA-TUFF™, a revolutionary new resin whose unique performance profile, offers manufacturers and OEMs, across multiple industries, a new solution for tough applications.

Extreme Impact Resistance

250% Greater impact resistance than Acetal.

Superior Chemical Resistance

Withstands constant exposure to PAA, sanitation and processing chemicals.

Exceptional Wear & Abrasion Resistance

Double (or more!) belt service life with zero broken modules.

ULTRA-TUFF™ Episode 1

Bullet Proof

ULTRA-TUFF™

Engineered Polymer for Today’s Food Safety Requirements

ULTRA-TUFF™ is an “eco-friendly” polymer, whose backbone consists only of carbons. It is highly crystalline with a compact, crystal structure, resulting in unsurpassed impact, chemical and abrasion resistance. Safari Belting’s ULTRA-TUFF™, is the only plastic modular belting on the market which can, simultaneously, withstand: High levels of drop-impact; Prolonged exposure to harsh chemicals (including PAA); and excessive wear from friction and/or abrasion.

*NOTE: Color variations, specks, or swirls are within quality specifications and do not effect the mechanical properties of ULTRA TUFF. They do not represent a manufacturers defect.

ULTRA-TUFF XMD™

X-Ray and Metal Detectable

Safari Belting Systems’ exclusive, high-performance, ULTRA-TUFF™ product lines are available in a Metal and X-Ray Detectable (XMD) formulation, which meets or exceeds the 1.5 mm ferrous equivalent standard, while maintaining high impact, chemical and abrasion resistance, making it the premier detectable belting on the market. Because ULTRA-TUFF™ is detectable by BOTH metal and x-ray detection equipment, it can be utilized across multiple applications, in numerous locations, making standardization simple.

Benefits

Dramatically Lower TCO

- Belting lasts 2 to 5 times longer

- Eliminating broken modules reduces downtime and maintenance expense

- Excellent release properties reduces trim loss

ULTRA-TUFF™

Episode 2

Log Splitting

ULTRA-TUFF™

Episode 3

Hammer Time

ULTRA-TUFF™ Belt Series

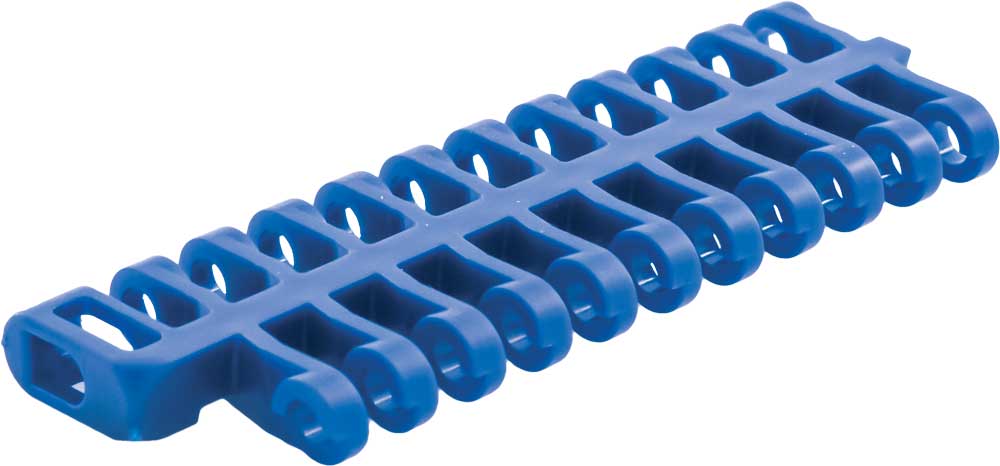

Series 250

Heavy Duty 2.5” Pitch

Series 125

Standard Duty 1.07” Pitch

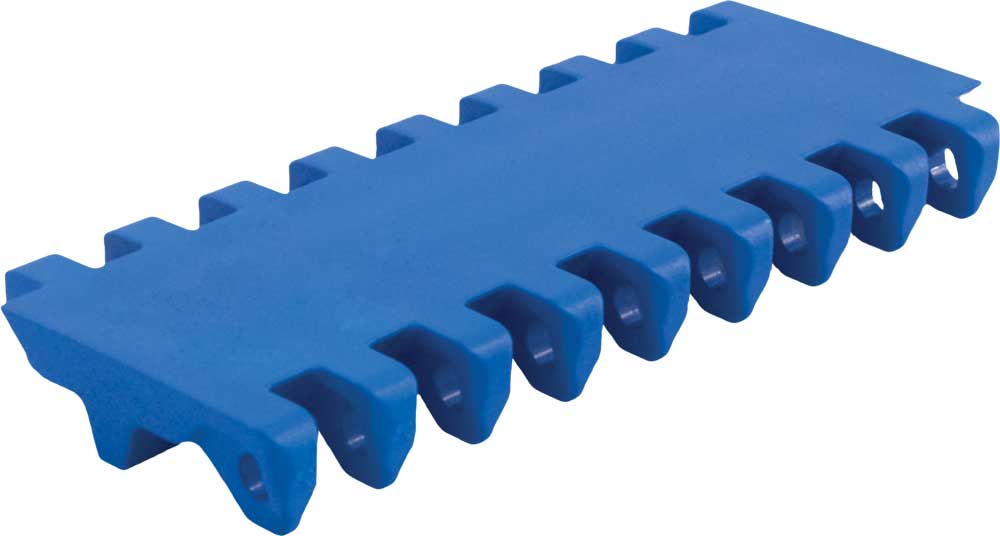

Series 225

Heavy Duty 2.0” Pitch

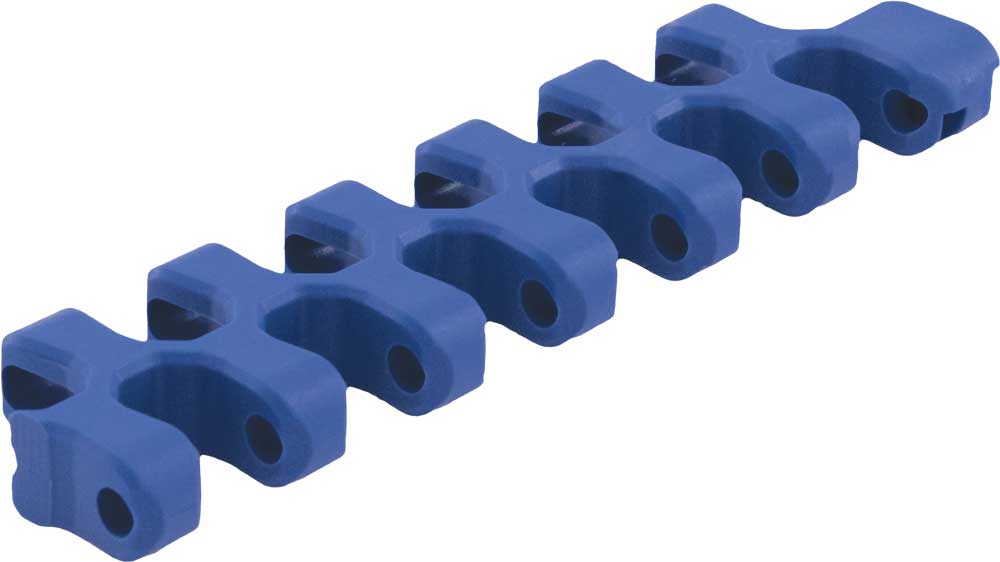

Series 500 (Radius)

Radius 1.0” Pitch

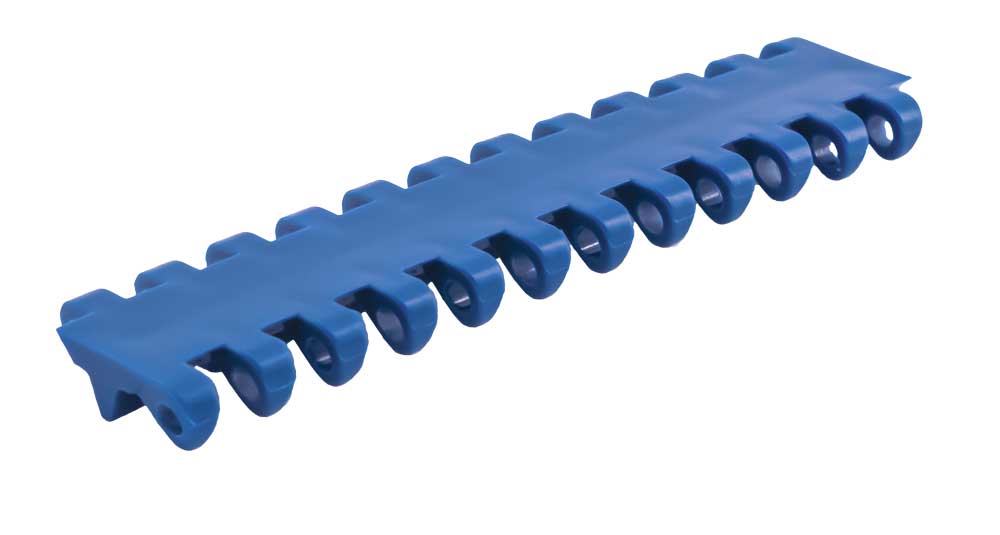

Series 150

Standard Duty 1.0” Pitch

Series 1100

Standard Duty .60” Pitch